| | lamune engine build (can engineer guy build a motor?) |  |

|

+14sherlock9c1 booster rcktpwrd goldwolfnhn 94Woody phantom 309 RedandBlack Eds rmw Fred Kiehl Rev Bob jasonlachapelle Gerome lakeffect lamune 18 posters |

|

| Author | Message |

|---|

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Fri Jan 17, 2020 10:00 pm Fri Jan 17, 2020 10:00 pm | |

| Fred I guess you're using an aftermarket head on your BBC? I don't think I'm far enough off to need Ford rockers though!

It's a stock LT1 Corvette head. They got milled down 8 thou but I don't think that'd change the geometry too much. And yes the fact they're aluminum does help the heat transfer and hopefully offset the slightly higher CR.

My friend told me that since we're not using a stock cam, the base circle may be different and that may explain why the stock pushrods are a little off. And also the fact that they are 18 thou longer than they're supposed to be. I never did hear back yet from the manufacturer as to why that might be.

I should have some time to look into that tomorrow and get the pushrod length sorted out.

Also I wonder if there's some way to estimate what the power difference (if any) that compression ratio may translate to. I'm going to have to dyno the wagon once the motor is done and assuming that it actually runs when I'm done. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Fri Jan 17, 2020 10:24 pm Fri Jan 17, 2020 10:24 pm | |

| I made the mistake of getting a set of aftermarket heads. If I were to do it again, I would buy name brand heads, and then I could use stock size rockers. The only good side to it is that the Ford rockers are 1.73 to 1, instead of 1.7 to 1. It makes my cam act like it is just a tiny bit bigger. I had the heads shave by 0.020, because the stock CR is only 8 to 1. I am at just below 9 to 1. The nice part is that I can run regular 87 octane gas. The heads are 112cc. I measured them with a plastic plate, syringe, and alcohol.

The only way to "gestimate" the HP is to find another one built like yours that was dynoed. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Jan 19, 2020 1:52 pm Sun Jan 19, 2020 1:52 pm | |

| Fred, nice. We have a "CC" rig in the shop but I did the same thing on the piston at home with a graduated syringe and trans fluid. Works the same way.

Anyway - pushrod length is still an issue. Had a massive geometry fail and thought the roller tip starts at the exhaust side and rolls across the the intake side during opening, only to read afterward that it's the opposite so my measurements are all backwards. I really had to rack my brain to understand and eventually figure out why that is. A literal "eureka" moment I guess.

So now that I know what to do I'm guessing the stock length 7.200" pushrods are probably close to correct. Since tomorrow is a holiday I might have time to go back with the adjustable pushrod and a black sharpie and get this squared away. I learned a lot about how the valvetrain geometry really works and that's good.

Also it looks like the pushrods I got that measured 7.218" are actually correct. The oiling tips stick out a little bit which adds to the overall length according to a tech document from the manufacturer. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Jan 19, 2020 5:27 pm Sun Jan 19, 2020 5:27 pm | |

| Mine hardly move across the top of the valve stem during the opening cycle. It would be smart to start at the exhaust side when closed, and end up just a little to the intake side when open. That way, you would be putting the most pressure on the valve when it is straightest in the guide. The positioning should not be super critical, as long as it is nearest the center for all positions. There will be only one position for the rocker with a given set of pushrods.

I used a test spring. It may have come from a wheel cylinder, but I forget where I got it. It was just enough to hold the valve closed as I cycled the crank and cam. That way I was not fighting a real valve spring during setup. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Jan 19, 2020 10:24 pm Sun Jan 19, 2020 10:24 pm | |

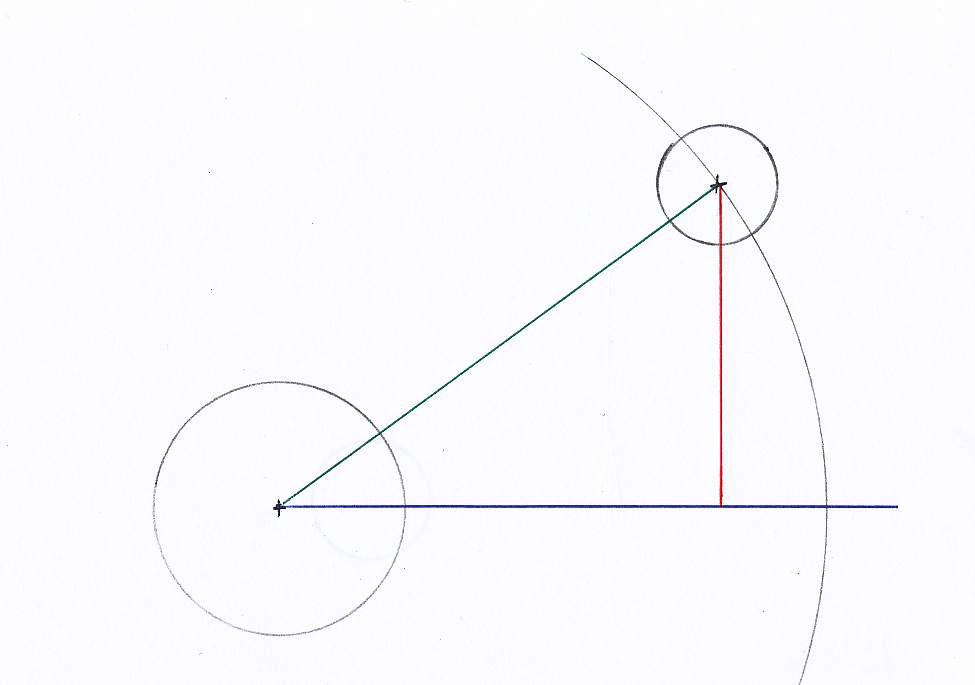

| Fred, it's interesting you say that. It might explain why my friend was also confused - the big block valvetrain geometry is not the same as the small block and he's basically exclusively a big block guy. Obviously in the ideal world the rocker arm would push down in the exact center of the valve stem and stay there during the open/close cycle. In the real world that doesn't happen but what we want to do is try and minimize the side to side effects and try and cross the centerline so we don't wear out the valve guides. The geometry in the SBC puts the rocker tip (roller in this case) above the pivot point of the rocker arm, meaning that as it travels downwards in its arc it moves linearly outward towards the exhaust header. This was what I didn't get but I sat down with a rocker, a compass and ruler and drew this out to check if what I was thinking was true. My high school geometry teacher would be proud. Note that this diagram is not to scale or anything even closely resembling such, but I hope it helps explain it if anyone else is unsure as to how this works.  | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Jan 20, 2020 8:27 am Mon Jan 20, 2020 8:27 am | |

| If that is the case, you should end up just a tiny bit past the center of the valve stem for maximum lift. The use of a test spring would make manipulating the valves easier. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Jan 20, 2020 12:06 pm Mon Jan 20, 2020 12:06 pm | |

| That's exactly correct Fred. I stole this image off SuperChevy, which shows the geometry as well. It seems very obvious now but man I struggled with this one. Maybe if I had looked at it from the side like this image, it would have made sense faster.  Maybe.  | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Jan 26, 2020 12:22 pm Sun Jan 26, 2020 12:22 pm | |

| Ok I think this horse is finally beaten to death. The magic number works out to 7.100". I had a problem when checking this time because the lifters bled down and the plungers were taking up huge chunk of slack that varied per lifter. We measured that distance and added it to the adjustable pushrod to compensate and I was able to get a good pattern. I think we're not going to get much better than this.  Also you can't see the roller tip because of the self-aligning wings. But this is what it looks like anyway.  | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Mar 08, 2020 6:31 pm Sun Mar 08, 2020 6:31 pm | |

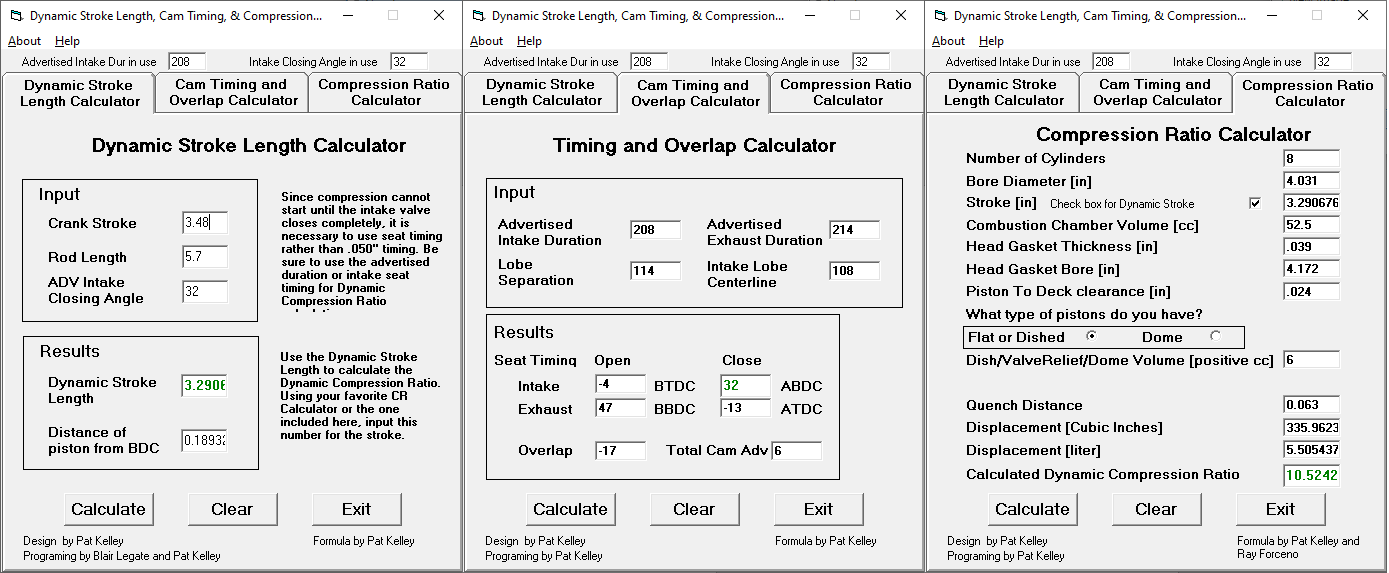

| I haven't had updates for a bit here, I didn't make major progress but was able to validate and correct a few things like valve spring installed height, etc. I think all the mistakes and glitches have been polished out and final assembly is around the corner at last. I'll spare the details of the self-inflicted dumb stuff I found. I'll just say, I learned a lot  One thing I didn't address here was the dynamic compression ratio. I tried a few different calculators and got wildly different answers from 7.5 to 10.5. The most comprehensive calculator I tried is the Pat Kelley one which gives the highest answer of 10.5 which sounds bad. The motor doesn't "feel" that radically different from a stock '95 F-body but I wanted to see if anyone had an opinion based on the data below:  | |

|

| |

94Woody

Posts : 2442

Join date : 2008-12-02

Age : 49

Location : Ocala,FL

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Mar 08, 2020 9:27 pm Sun Mar 08, 2020 9:27 pm | |

| Why does 10.5 sound bad when that is the same as a stock Aluminum Head LT1? | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Mar 08, 2020 11:16 pm Sun Mar 08, 2020 11:16 pm | |

| I forgot to add the reasoning behind why I question if that number makes sense. This isn't something I'm terribly familiar with. Maybe someone here can shed some light onto this and how it relates specifically to the LT1. The guy who made that DCR calculator has on his page a note about it which I'll quote below from http://cochise.uia.net/pkelley2/DynamicCR.html - Quote :

- Why it matters: A 355 engine with a 9:1 static CR using a 252 cam (110 LSA, 106 ICL) has an intake closing point of 52º ABDC and produces a running CR (DCR) of 7.93. The same 9:1 355 engine with a 292 cam (having an intake closing point of 72º ABDC) has a DCR of 6.87, over a full ratio lower. It appears that most gas engines make the best power with a DCR between 7.5 and 8.5 on 91 or better octane. The larger cam's DCR falls outside this range. It would have markedly less torque at lower RPM primarily due to low cylinder pressures, and a substantial amount of reversion back into the intake track. Higher RPM power would be down also since the engine would not be able to fully utilize the extra A/F mixture provided by the ramming effect of the late intake closing. To bring the 292 cam's DCR up to the 7.5 to 8.5:1 desirable for a street engine, the static CR needs to be raised to around 10:1 to 11.25:1. Race engines, using high octane race gas, can tolerate higher DCR's with 8.8:1 to 9:1 a good DCR to shoot for. The static CR needed to reach 9:1 DCR, for the 292 cam mentioned above, is around 12:1.

| |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun Mar 08, 2020 11:24 pm Sun Mar 08, 2020 11:24 pm | |

| Put that puppy together, and run premium in it for the time being. You can always revert back to regular if you have a knock sensor. You can even "test" different grades of gas if you know what "knocking" sounds like.

The problem with engineers building something is that they want to know every detail, and won't go forward unless those petty details suit them. Get it running, and then sort out the details. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 1:04 am Mon Mar 09, 2020 1:04 am | |

| I hear you Fred. This isn't a stopper or anything, I just didn't do it and was wondering if those numbers were right and what (if anything) it implies.

This build doesn't seem different enough from the F or Y body LT1 to worry about it blowing up (at least not for that reason) 10.8 stock vs my 11.1 static ratio doesn't seem very different to me. And yes I will be starting out with fresh 91 octane just to make sure since that's what the contemporary Vette recommends.

I should hopefully have it closed up and primed next week. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 2:41 pm Mon Mar 09, 2020 2:41 pm | |

| Also that reminds me, I need to figure out an easy way to drain the tank. Running the fuel pump seems easy but that might make a huge mess. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 7:35 pm Mon Mar 09, 2020 7:35 pm | |

| There is no other way that is less messy. Drain it into a gas can, or two. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 8:15 pm Mon Mar 09, 2020 8:15 pm | |

| I was thinking that it must come out under pretty extreme pressure- what should I expect? | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 8:34 pm Mon Mar 09, 2020 8:34 pm | |

| If you put a hose in a gas can, it will just fill the can. Do not let go of the hose, and you will be OK. You can use the pump bypass connector on the fuse block, and put a push button switch in the wire to allow you to release it to shut the pump off. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Mar 09, 2020 9:54 pm Mon Mar 09, 2020 9:54 pm | |

| Thanks for the tip Fred, I'll get that tank drained shortly.  | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 24, 2020 4:43 pm Sun May 24, 2020 4:43 pm | |

| Hi all, things have been slowed down but I'm still making progress. I'm ready at this point to fill and prime the oil system and install the intake manifold and close everything up. Thanks for all the support and help.

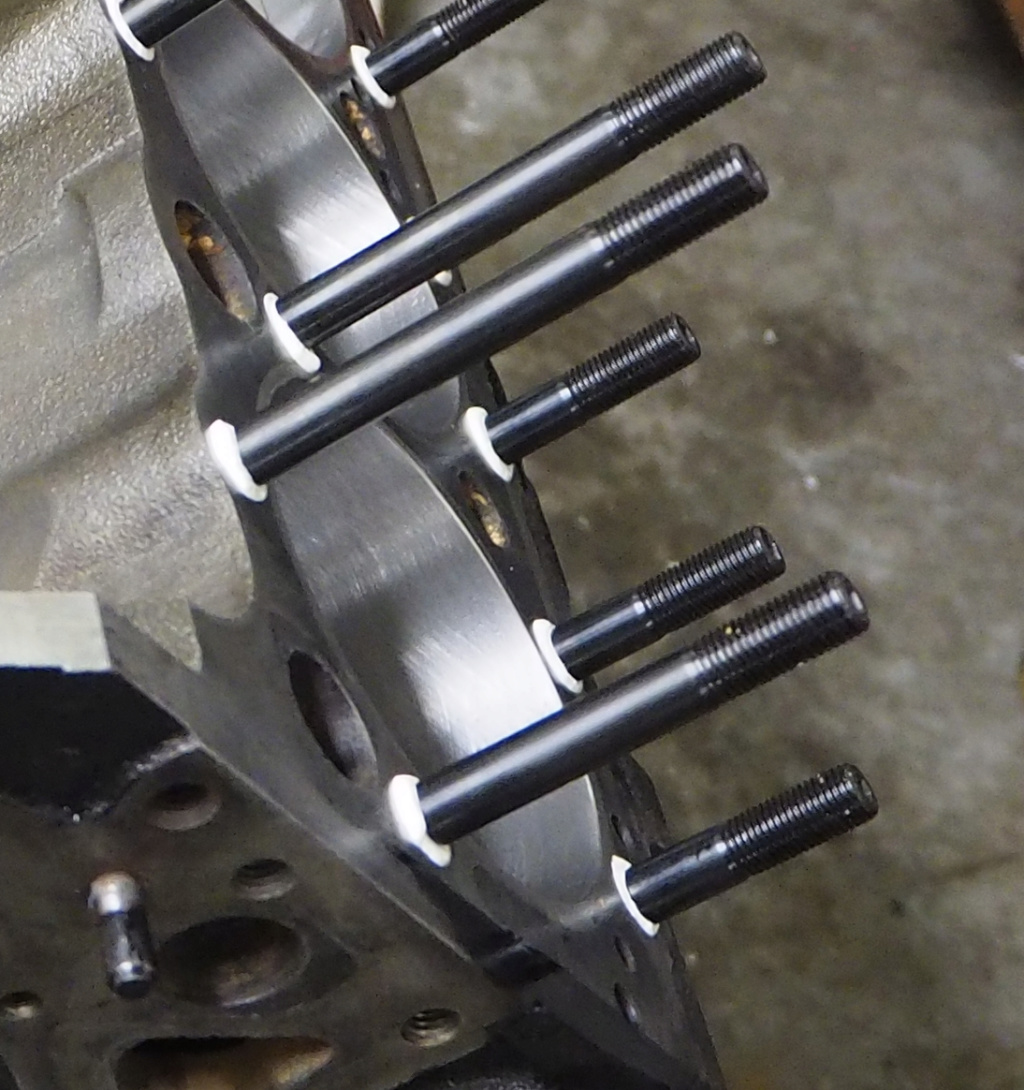

We did happen to notice that some of the rockers are incredibly close to the head studs. One or two appear to be basically in contact. Some questions we had about this since we're kind of on our own with this set up.

How much clearance is necessary between the rockers and the head studs? 10, 20, 40 thou?

Two methods came to mind. Method one would be to remove the rocker, cover up everything as best I can and put magnets nearby, and hand file the head stud down. This doesn't disturb the head gasket but could result in some metal bits getting into the motor.

Second method thought of is to remove the impacted head studs one at a time and grind them down outside the motor. This keeps the metal bits out of the motor but might conceivably disturb the head gasket seating.

Any thoughts or previous experiences to share would be helpful. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 24, 2020 5:42 pm Sun May 24, 2020 5:42 pm | |

| Did you consider using slightly longer push rods to raise the rockers. No grinding or filing necessary. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 24, 2020 6:23 pm Sun May 24, 2020 6:23 pm | |

| Fred, in order to get the rollers centered on the valve stems I had to put in .100 shorter pushrods, which is apparently where the problem stems from. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 24, 2020 7:56 pm Sun May 24, 2020 7:56 pm | |

| Maybe the rockers are not right for the application. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 24, 2020 11:17 pm Sun May 24, 2020 11:17 pm | |

| | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 12:46 am Mon May 25, 2020 12:46 am | |

| The 1/10 of an inch shorter push rods seems like a lot even for re-remanufactured heads. I am not familiar with the rocker arms. Have you tried others to see how they fit. Do the stock ones require the same push rods? You could test fit one for reference.

I ended up using a ford rocker arm on my aftermarket heads on my 454. The chevy rockers were too long no matter what length of pushrod I used. Scorpion helped me out with that issue, by sending me a couple of different rocker arms for testing. Comp Cams may give you the same courtesy. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 12:03 pm Mon May 25, 2020 12:03 pm | |

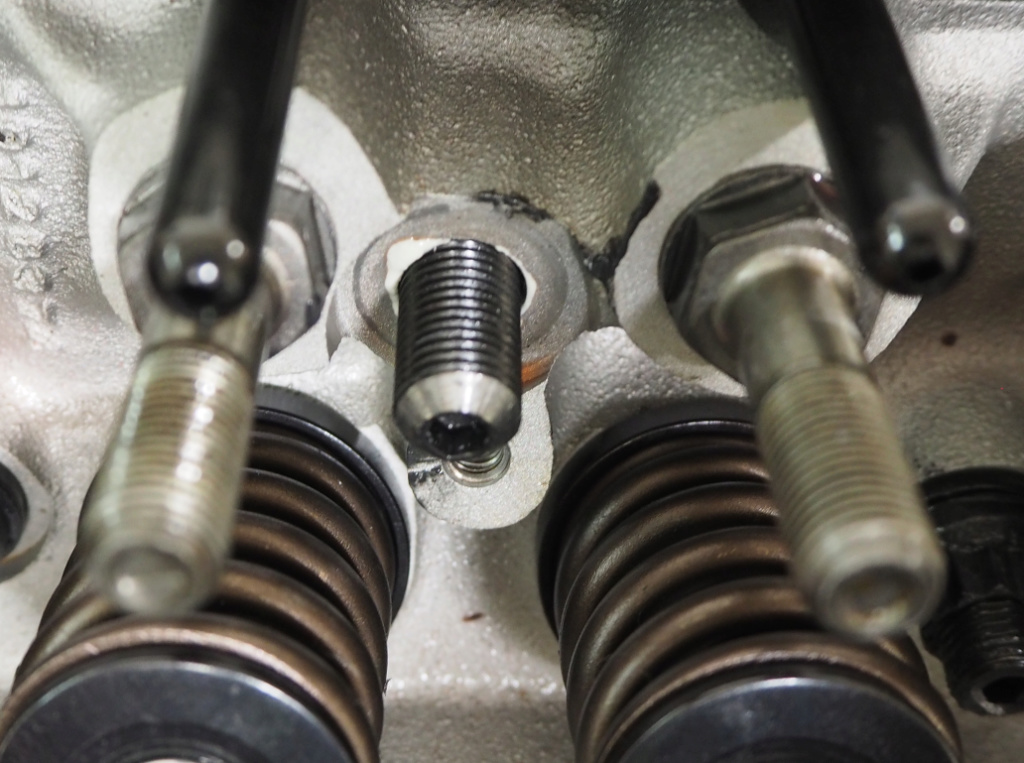

| Certainly I'd have no problem with a stamped rocker.  Maybe an example picture would help:  | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 2:15 pm Mon May 25, 2020 2:15 pm | |

| OK the studs are too tall I would not take any off of the top, I would remove a thread from the bottom You need the meat around the hex for removal. Can you screw the studs in any further? | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 5:02 pm Mon May 25, 2020 5:02 pm | |

| Studs are bottomed out as per the instructions. To do what you're suggesting, I would need to remove the stud and cut some more threads into it get it to bottom out further. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 7:55 pm Mon May 25, 2020 7:55 pm | |

| Cut the end off of the stud, and dress it. If it has a thin shank at the bottom, emulate it. 1/16 of an inch should be sufficient. You can do it with a bench grinder if you are careful. It could also be done in a lathe. I have done worse things to bolts. You only have to do the ones that are too close. You do not have to tap any further into the hole. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 8:47 pm Mon May 25, 2020 8:47 pm | |

| Fred, cutting the end off the stud bottom won't help, because the holes are clear into the water jacket and the studs bottom out on the shoulder where the threading ends. To make it thread into the hole further, you'd have to make the stud's bottom threaded portion longer by cutting more threads. I don't think that's feasible. Unless I'm just misunderstanding what you're suggesting.

I'm not clear what negative effect grinding a few ten-thous off the top of the stud would do though, aside from generating debris that I don't want inside the motor if I did it in-place.

Would removing one impacted stud at a time, grinding the top down a bit and replacing it cause any sort of problems with the head gasket? It's still clamped by everything else, and it's never been run, so my guess is that it would be fine to do that too. (But that is just a guess). And yes you are totally correct that not all of them have a clearance problem. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon May 25, 2020 11:28 pm Mon May 25, 2020 11:28 pm | |

| So there is a point where the stud runs out of threads and has a non threaded shoulder, and can no longer be threaded further into the block, when screwing it through the head. Does the shoulder pass through the head, and contact the block? If so, then, yes you will have to remove the top for clearance.

When you stated that it bottomed out, I assumed that bottoming out means that it hit the bottom of the hole it is threaded into, not that the stud has a shoulder that keeps it from threading further into the block. Have you checked to see if the stud is actually hitting the shoulder, and not the bottom of the threaded hole. Some of the holes in the block have a lip on the inside of the hole that can act like a full bottom of the hole when threading a stud into the hole. If the studs are all the same height above the nut, it probably is not an end of the hole on the ones that interfere with the rockers. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Tue May 26, 2020 12:37 am Tue May 26, 2020 12:37 am | |

| Sorry, my terminology was confusing. The stud shafts are larger in diameter than the threaded sections and are designed to stop at a specific point when fully threaded. I have a lot of pictures and I can say for certain that they are all completely threaded in and the amount of thread sticking out past the top nut is the same on all of them.

I still have to come up with a go/no go clearance. One thread is about .040, maybe I'll go with that. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Tue May 26, 2020 7:27 am Tue May 26, 2020 7:27 am | |

| From what you said, you will be removing enough of the top to give you clearance. A common clearance for solid lifter valve lash is between 0.010-0.020. There will be some expansion, but that should be a guide for minimum cold clearance. Your guess at 0.040 would be acceptable to me. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Tue May 26, 2020 12:20 pm Tue May 26, 2020 12:20 pm | |

| .040 is probably excessive but I'd rather only do this once. Any thoughts on potential problems of pulling and reinstalling studs on the integrity of the head gasket? Here's a cropped shot of what the studs look like when they go in for reference:

Last edited by lamune on Tue May 26, 2020 4:50 pm; edited 1 time in total | |

|

| |

rcktpwrd

Posts : 577

Join date : 2019-03-06

Age : 50

Location : Raleigh, NC

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Tue May 26, 2020 2:53 pm Tue May 26, 2020 2:53 pm | |

| I don't think you will have any issues at all pulling one stud at a time...

I would trim just enough off the top for the clearance you need/want. Might also be a good idea to leave the nut on the stud or use and extra one if you have it to clean up the threads with. Or better yet a thread chaser if you have one... | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Tue May 26, 2020 3:24 pm Tue May 26, 2020 3:24 pm | |

| A couple of things that might have saved some of the hassles that since it is a fresh build you have options as to when the valvetrain stuff gets sorted out.

I usually use a bunch of setup parts to do it before final installation of the heads or intake, and even better without the timing set in. Works especially well if you can see the cam well enough to know if you are on base circle.

I make or buy some setup washers to replace the headgaskets, which are basically aluminum washer at the thickness of the compressed head gasket. Use them to assemble and just snug the studs.

Disassemble some old lifters that have the same free height and travel as what you are going to use and put spacers in them to hold them solid. If you have an engine were you can get the lifters out without removing the heads you only need to do one.

Use weak springs as Fred suggested as it really makes life easier.

If you can lay your hands on an adjustable pushrod, it will speed things up a lot.

Put it roughly together with the setup parts on the valves you want to check.

Turn the cam or engine to get the valve you want on the base circle.

Hold the rocker lightly down on the valve tip and adjust the nut until the rocker angle is what you want with the pushrod adjusted loose and not touching. This sets your rocker/valve geometry.

Adjust the pushrod until you just get contact using the good old spin the pushrod test. Lock the pushrod length and remove it. It is now the correct length for zero lash with your chosen rocker position to the valve, the lifter full with no preload, and on the base circle of the cam. Measure the pushrod length and add 1/2 the travel in the lifters you will be using. That is the length of the pushrod you want to have with everything where you want it and with proper lifter preload.

If the valve tip heights are well done, which is always a question for some reason, and the pivot points the same, all the valves should be good with that pushrod length if you check a few and average. Do minor adjustments the old fashion way after the it all assembled to do a final on the preload for each cylinder with the rocker adjustment. With good machining you would be able to get by with only one valve checked, but I usually would do one intake and one exhaust on each side to do the averaging.

You will know if you are good when done and the final preload is set as the rockers when closed would be in identical position and the contact patch on the valves the same between all the intakes and between all the exhaust which will possibly have different amounts of lift.

This will also allow you to find any interferences or no fits of bad parts like the stud interference, and you will also be able to set the intake in and see that ports are going to line up and bolts all line up. | |

|

| |

Fred Kiehl

Posts : 7290

Join date : 2009-11-13

Age : 76

Location : Largo, FL 33774

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Wed May 27, 2020 8:03 pm Wed May 27, 2020 8:03 pm | |

| You should not have a problem removing single studs. Make sure you put new sealer on the threads. Torque them down to the same spec as they were. | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 9:53 am Thu May 28, 2020 9:53 am | |

| Just a quick question, did you get an actual weight on the Mahle pistons you used? It is often stated that the LT-1 used lighter pistons than the the plain 5.7, at 532g, and wondered how these came in compared to that. Manufacturers do so many supersedes these days things are always suspect, but I would hope Mahle would still have OEM style as they made the originals for GM it appears.

Of interest to me is that the forged pistons that I have found in quick look appear to be lighter than 532g and the cast pistons higher at in the 550g range. These are all generic small block pistons, though.

For me, the .063 quench would be too much, as the quench gets much less effective when it gets that high. Not open chamber bad, but certainly not ideal for efficiency or detonation elimination. The problem comes in keeping the compression under control if you go to zero deck to get the .040 or even .038 quench with the tiny combustion chambers and the only real way to do it is with a flattop with full quench pad and valve relief dish in that area only. The Keith Black KB193 and KB142 would be the top choices as they have 12 or 18CC plus volume, which would get the compression back to the right range. Problem is that both are at 550g+ so would mess up the balance if the the 532g stock is the correct number. Adding weight to a crank for balance gets a lot more difficult and costly than taking it off so perhaps a swap to a stocker old school 5.7 would be better if you it isn't allowable to reduce piston weigh that much. I will have to get a hold of KB and see what the max removable is, but cast pistons often don't allow much. The fact I would be doing a low rpm milder engine should allow a bit more weight to be removed. | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 11:29 am Thu May 28, 2020 11:29 am | |

| I just took a look at the crank you got, although I wouldn't be going stroker. Very reasonable for what it is when comparing to doing a good regrind and polish.

Specs would indicate it is a generic 350 one piece seal setup, and they have a note that says "needs to be balanced" which usually means they have some extra weight in the throws to allow for using a wide piston weight range without having to add Mallory. If they are covering the very wide range to include the quite old piston weights, blower pistons, etc, it could have quite a bit of extra weight. This is a good thing, IMO, as it give lots of options in use, and you really need to balance unless you get exact same piston and pin weights when changing and using the same rods and crank.

Did you balance? If so, how much was needed to handle the pistons/rods you got? | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 1:12 pm Thu May 28, 2020 1:12 pm | |

| Thanks all for the info. I'll let you know this weekend what we end up doing. Maybe I can chuck them in the lathe and turn the head down a bit, that might be cleaner than using the usual belt sander method. Booster we did most of what you described in your post as far as setup goes, but I really like the use of the aluminum washers to do a full mock-up to find/fix issues before you commit your head gasket. If I do another build I'll do that. Also as far as crank goes, the stroker crank is sitting in a box in my garage and a stock-like SCAT is in the motor. Yes I did have the assembly balanced. The stock one was balanced to within something like 2g. (actually, both assemblies are balanced, and the stroker does have mallory added to it) Anyone want to buy a 383 balanced assembly?  I probably do have the piston weights on the balance card which isn't here. I do have an extra piston and a postal scale. The postal scale says 530g with a resolution of +/- 5g so it's within the spec and the poor resolution of the postal scale. If I did do this again, I would do a lot of things differently, that's for sure | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 4:13 pm Thu May 28, 2020 4:13 pm | |

| lamune, thanks for the information. Was the Scat crank a generic 5.7 stocker replacement or and LT-1 specific one?

Yeah, the aluminum washers got to be an absolute necessity when I was doing the turbo motors, as I needed to know the exact compression ratio and have it exactly the same between cylinders to get decent information once it was in use to apply to future changes if needed. I would always do an early dry run with the crank in, pistons with no rings to check deck height. Since I always try to use full floating piston pins, I could move the stock forging rods around to use the tolerances to balance the deck height to best uniformity. For me, having the washers and adjustable pushrods saved many hours of work in getting things to the best fit and uniform. When done well, I could run stock like skirt clearances with low expansion Diamond forged pistons and stock width rings with very tight quench. | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 5:34 pm Thu May 28, 2020 5:34 pm | |

| I just got an answer back from KB pistons manufacturer about the previously mentioned flattop dish pistons that are too heavy for the LT-1 crank balance.

They came up with an excellent suggestion. If you go with the R20 tool steel piston pins, you save 27g, which put you right on for the 18CC volume, and actually a bit lighter than stock on the 12cc volume pistons. Both would make balancing much easier and you would maintain the lighter rotating assembly of the LT-1. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Thu May 28, 2020 11:04 pm Thu May 28, 2020 11:04 pm | |

| Cool. This build is really a stock replacement with some slight adjustments. What I have is closer to a stock F-body motor with some minor upgrades than anything else, I would say. I'm OK with that as a first build attempt. I am enjoying the process, so maybe I'll build another one when this one is done and running.

The 350 crank in the motor is a SCAT 9-10526 and the 383 crank is a PBM 70002 which is made by SCAT. Neither one is LT-1 specific. I don't think SCAT has anything LT-1 specific, at least not that I saw. | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Fri May 29, 2020 9:35 am Fri May 29, 2020 9:35 am | |

| It actually has been pretty interesting looking into it all for the LT-1 engine, as is different by a bit from what I am used to seeing in the older Mopar engines.

The last of the turbo 340 engines I built was actually kind of similar to the high velocity, fast burn heads that GM had/has, but it required 1988 318 engine heads on a 340 to do it. Closed chamber, flush quench pad, wedge head. Big difference was in the chamber size, which was much larger.

The LT-1 is an obvious design of similar type, with a smaller chamber than most and the reverse flow cooling. The original design specs were probably 4.000 bore, 3.48 stroke, 53.5cc chambers, 12cc piston volume, .039 head gasket, and .006 down the hole, all of these specs keep coming up in research often. This gives almost exactly 10.5 compression on the the calculator and an acceptable .045 quench distance. Tolerances would require the 6 down the hole to prevent going under .040 which often considered as low end for quench. Those specs give a very good design and efficient fast burn and high velocity with relatively small ports and valves. The good specs for torque/horsepower/mileage all confirm that. Probably the only compromise is the extra two valve reliefs near the quench. Many of the engines seem to actually be reporting less than the spec combustion volume also on uncut heads which may explain why many, but not all of the people report some detonation as that 1-2cc would raise compression by .1-.2 point .

It all goes south really quickly in the real world of rebuilding, with the quench probably getting hurt the worst. The piston people know that the heads and block are going to be cut on nearly every rebuild engine, which will reduce chamber volume and also reduce the amount the piston is in the hole, so the shorten up on the compression height of the pistons to take care of the block cut and put a little dish in them or make the valve cuts bigger to take care of the combustion chamber. Quench winds up at closer to .060 and gets pretty inefficient. Having lower quench certainly could cause more detonation depending on how susceptible the engine is to it. Burn speed will also slow down so the timing may need to back off a bit. When I compared the timing optimization between a full open chamber 340 with the closed chamber small port 340 engine, the most efficient timing at 60 mph (about 2100rpm) was nearly 20 degrees less advanced for the fast burn high quench engine. Detonation threshold moved from 8+9 psi boost to 15, even though it had a compression increase from 8 up to 9 on iron heads.

All this tends to point to the very common problem of losing a bit of efficiency on stock rebuilds, although it is not often noticed by any other than hard core observers because the previous engine was in poor to horrible condition.

I think this would all point to getting to a piston like the KB mentioned is a good idea, if it is in the budget, for a high quality rebuild. It would be even more important, IMO, if you are looking to get and upgrade in power with more cam, airflow, etc. The tool steel pins to get closer to the stock weight for the piston ends adds over $100 it appears but if the balance needed mallory because of not doing the pins, that might balance out in cost. KB pistons are also somewhat more expensive than quality rebuilder pistons, but not a lot.

As mentioned, a very interesting exercise into how it all works together in the LT-1 engine. Hopefully, my engine will continue to function well for a long time, but at least now I know what I would do if it does need to be rebuilt. Doesn't look difficult at all to do a very good rebuild with off the shelf parts and keeping most of the stock guts. Cam, lifters, rockers, pushrods, and pistons would the only real changes I would do, I think.

| |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sat May 30, 2020 9:45 pm Sat May 30, 2020 9:45 pm | |

| Booster I think you're pretty close, but from what I've seen the factory piston spec is about .020 down in the hole. The head gasket has "pockets" I guess you'd say that probably make up the volume difference. With the piston .020 down and taking those pockets into account I get the factory CR with those specs. I didn't find any definitive spec on how far in the hole the factory depth would be. I did find one source on the internet that said .017 but what's 3 thou among friends? I didn't measure how far down in the hole the stock pistons in the motor were before I took it apart. If I come across one I'll compare and let you know. However Mahle swears up and down that what I put in is a direct OEM-spec replacement for what was in there. I don't have any reason to doubt that replacement pistons may be made to compensate for machining of old blocks out there on the market. Gotta measure everything and assume nothing. I learned that doing this rebuild, that's for sure. Today I went down to the shop and after talking about various things we could do, we settled on machining a 45 degree chamfer in each of the studs. Since there's only 8 we just did them all one at a time. I ran out of time to re-adjust the valves, but next time I'm there we will see if the modification was effective. Also I'd love to see what a nicely built 340 looks like as it goes together.   | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sat May 30, 2020 11:29 pm Sat May 30, 2020 11:29 pm | |

| It probably is the difference in the release specs, which is likely what I saw, and how production actually turned out. Since nearly all the chambers are at least 1cc less than the spec I had, the guess would have to be they weren't cleaning up at design cut. They may have just adjusted the combustion height lower to allow for the changes to other tolerances and put it deeper in the hole. Stuff like that happened all the time before better engineering, tooling, and process controls were introduced. The fact that the specs I had calculated right to the claimed compression ratio would also indicate engineering specs I think. Most of the non modern engines that I have heard about being blueprinted were far off of design specs, so the blueprinting was really necessary. I would guess you could probably blueprint a modern Lexus engine by waving a wand over it as it unlikely it would have anything out of spec, I think.

I think at one time you or someone mentioned another piston that would have been different amount down the hole, but I don't recall how much, or which way? | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 31, 2020 10:51 am Sun May 31, 2020 10:51 am | |

| I did a little exercise in digging up information this morning to try to see if I could find tear down information on the (assumed) original engines that hadn't been internally touched. Very surprised, even with low expectations going in, at the variations I found.

The most common measurements lined up more closely with what you have found and it appears the aftermarket pistons are giving. .020 down the hole, mid 52cc chambers, .049 head gasket. One mention says the rebuilder spec allows to go to 51.9cc on the chambers. These numbers gave just under 10 compression ratio, which from what we have almost always seen in the older engines which tend to stay under, rarely over, on compression by varying amounts is not a big surprise.

It did seem that that the most variable thing I saw was the deck to piston height, with finding of .025 down to actually out of the block. I put the numbers in the calculator all the same but at zero deck instead of .020 and got very close to the 10.5 compression ratio, so it met that part of the spec.

Several places talked about the deck height being substantially different bank to bank, which is really not a good thing, and speaks to the very poor process control of the era.

Bottom line, it appears is that most of the engines were probably in the 10.0 range for compression and not at 10.5, but some probably were at 10.5 and some probably under 10.0. Completely explains the different detonation observations, which seem to be pretty common. My Buick does not get detonation that I have noticed. It is too bad the Scangauge doesn't show the knock retard for this engine, as that would tell if it is there very quickly. I can see it on the 6.0 in our very heavy van RV, but you don't hear it there either and it is only for a second or less.

It also says that most of the engines had a quite large quench distance, .070 in the example of the most often seen numbers.

All of it comes together in that if you want good quench of .040 at 10.5 compression (without an extra set of valve reliefs) it won't happen with off the shelf parts that are for an LT1 engine as you have to increase the volume of the piston or combustion chamber to do it, and you won't get that much out of the chambers. It appears that most of the places I saw did not worry about the quench height, which was a bit surprising to me, as mostly stock part rebuilds were the norm, with strokers next and many of those were done with all non standard parts and most tightened up on the quench. Some of the strokers were done with the parts and specs that were very finely tuned.

An interesting exercise, certainly points out how the more modern tight quench, small port, high velocity engines require a lot more correct interactions of parts to be optimized. In the day of open chamber heads deck to piston didn't mean much so all you really needed to do was get the right compression to match the head and gasket volumes by positioning the piston and then check valve clearance for interference and maybe reliefs. Very easy to find and select parts. | |

|

| |

sherlock9c1

Posts : 2399

Join date : 2009-05-28

Location : Huntsville, AL

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Sun May 31, 2020 11:02 pm Sun May 31, 2020 11:02 pm | |

| Are you talking about original 94-96 LT1 engines? When I was building my motor I found:

Iron Head chamber: 63 CC

Piston relief: 5 CC

Piston height: 0.025" in the hole (average)

Head gasket: 0.029" thickness

Aluminum LT1 head chamber: 54 CC (for both LT1 and LT4)

Piston relief: (same 5 cc)

Head gasket: 0.048" thick

Do note that the aluminum head gasket often gets included in rebuild kits and if you put that on an iron head motor, you'll have a noticeable loss in compression (and crappy quench too).

Having spoken with someone familiar with GM engine manufacturing at that time, they had to leave that much room for tolerance stackup (0.025" in the hole, 0.029" gasket). If you take the time to measure your exact engine, you can buy Cometic gaskets at a custom thickness to minimize your stock motor's quench height and maximize compression for better torque and economy. But at that price and since you have the heads off you could always update the heads and use a Fel Pro 1074 (0.040"). | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Jun 01, 2020 10:16 am Mon Jun 01, 2020 10:16 am | |

| I don't have a history in GM at all, but I think I have heard a couple of times that the 64cc would be more like a Vortec head combustion chamber volume. Do Vortec heads fit the LT-1? If so, that would also explain the .029 head gasket to get the volumes back to get the right compression ratio. The calculator would put that engine at 9.8 compression ratio. Were the valves sunk really deep?

All the information I have found says both iron and aluminum at 53.5cc design but most running smaller with the rebuilder spec at 51.9cc. Those 10cc in the head would make over 1 full point of compression ratio, so really messes things up.

The "normal" method I am used to of getting compression ratio and quench would be to set the quench to .039 with an off the shelf head gasket, get the compression height on the piston at zero deck if possible or have the block cut (which you should do anyway to straighten it out) to get zero to .005max down. You then do you calcs to determine the amount of volume you need in the non quench section of the piston to get compression ratio. You may get to it with the valve reliefs in some engines, but many will require a pocket which is very common now and nice because no sharp edges to get hot or disrupt flow. If you are on a budget and no piston gets there, you can go back and play with the head gasket thickness or deck cut, or head cut, to get where you need to be to match a stock piston. If your initial measurements indicate a stock piston is close, you can do the same routine backwards to get the block and head cuts and gasket.

I need to look into what head gaskets are called out for the iron head cars and aluminum head cars to see if I can find any difference there. | |

|

| |

booster

Posts : 608

Join date : 2020-04-21

Location : Andover, Minnesota

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Jun 01, 2020 10:25 am Mon Jun 01, 2020 10:25 am | |

| I just looked at Rock Auto, and when I pull up head gaskets only, not kits, for 1995 Caprice (iron), and Corvette (aluminum) they are all listed as being .048/.053 range. One gasket in the list showed in the .025 range, but in the actual listing spec said .050. At least in the aftermarket, they are all .050 or so now.

Did go back further to GMpartsdirect, which don't list the head gaskets in gaskets, but do show as unavailable in the whole engine blowups. Then did a search and the show up at Summit and others 12553160 for Caprice and 10168457 for Corvette and Camaro. They do show a different thickness with them as you state. On the calculator, assuming 5cc in piston, 64cc chambers, that turns it into a 9.5 engine if someone puts a .048 gasket on it, 10.0 if they put a .024 gasket on it. The thin gasket would get quench a lot better, although still with the extra valve cuts. The cuts that were shown on the Mahle pistons also looked to be a bit bigger than 5cc, but pix make it hard to know for sure. The thin gasket would give about .050 quench which is certainly getting into the decent range, especially if you have the turbulence from valve cuts disrupting it if they overlap the head quench pad area.

I have not been able to find anything on the 64cc chambers for LT1 yet, but still looking. What year was your engine? A lot of it would depend on that being 64cc to be able to get the quench improvement.

All very interesting, and with all the reading I have done, have not run across it anywhere else. It wouldn't be a big deal for me in a rebuild as I measure everything twice at disassembly and calc the compression ratio and quench so it would get caught, but that is not the norm for home rebuilds or valve jobs at home or in a many shops. There may be a whole lot of 9.5 compression ratio huge quench engines running around out there. | |

|

| |

lamune

Posts : 868

Join date : 2014-05-09

Location : Seattle

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  Mon Jun 01, 2020 11:46 am Mon Jun 01, 2020 11:46 am | |

| If you want to see what I came up with for the build specs, here's my spreadsheet CR CalculatorI did not take into account the area between the top ring and piston crown which would bring that number down by something | |

|

| |

Sponsored content

|  Subject: Re: lamune engine build (can engineer guy build a motor?) Subject: Re: lamune engine build (can engineer guy build a motor?)  | |

| |

|

| |

| | lamune engine build (can engineer guy build a motor?) |  |

|